Introduction

I'm Sasaki from the Global Engineering Department of the GLB Division. I wrote an article summarizing the content of the session based on the report by Mr. Kanamaru, who is participating in Data + AI SUMMIT 2023 (DAIS) on site.

Articles about the session at DAIS are summarized on the special site below.

The future of factories will be more automated with data and AI

This time, I will cover Accenture's talk "Factory of the Future: Case Study of Building Digital Twins Using Knowledge Graphs and Generative AI". In this talk, he introduced how to simulate the reconstruction of a factory using a digital twin, and how to use data and AI to realize factory automation. It's interesting for factory operators, data scientists, and AI engineers.

This time, I will cover Accenture's talk "Factory of the Future: Case Study of Building Digital Twins Using Knowledge Graphs and Generative AI". In this talk, he introduced how to simulate the reconstruction of a factory using a digital twin, and how to use data and AI to realize factory automation. It's interesting for factory operators, data scientists, and AI engineers.

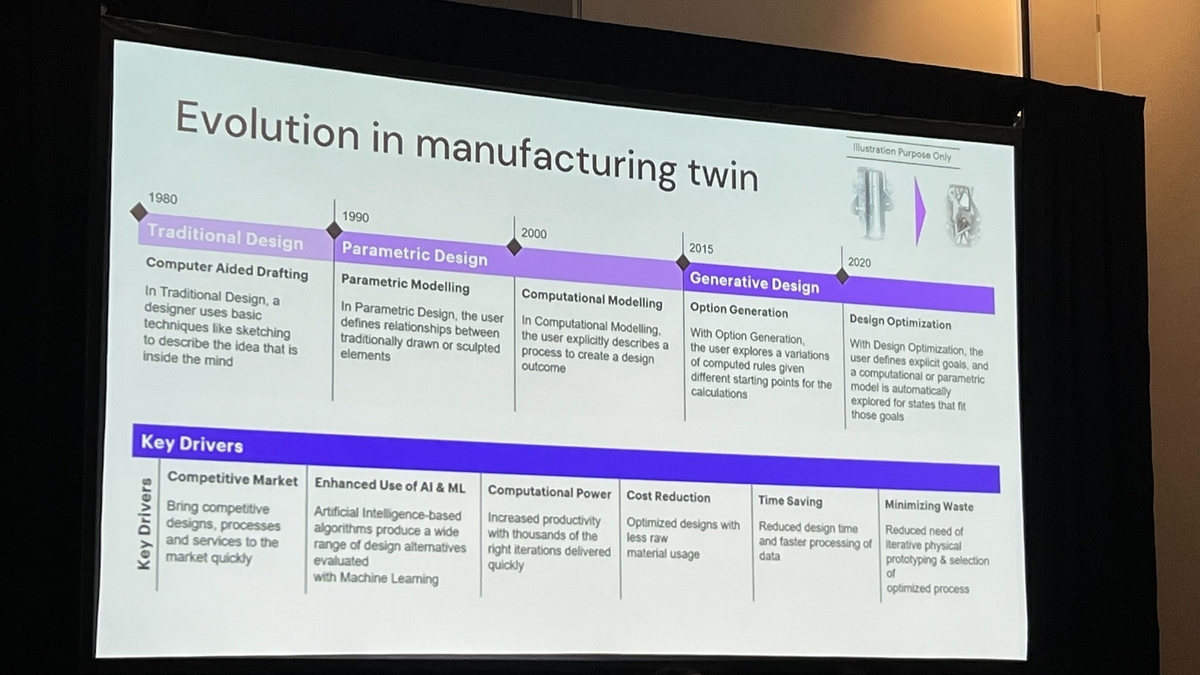

Background and utilization of digital twins

A digital twin is a virtual model that digitally reproduces a physical object in the real world. This makes it possible to grasp the status of factory operations and equipment in real time and achieve optimal operations.

Examples of the use of digital twins include equipment status monitoring, virtual testing, and optimization of production plans. Through these examples, it becomes possible to construct an efficient production line and optimally allocate resources.

A digital twin is a virtual model that digitally reproduces a physical object in the real world. This makes it possible to grasp the status of factory operations and equipment in real time and achieve optimal operations.

Examples of the use of digital twins include equipment status monitoring, virtual testing, and optimization of production plans. Through these examples, it becomes possible to construct an efficient production line and optimally allocate resources.

Factory reconstruction simulation using digital twin

Accenture's presentation introduced a case study of a factory reconstruction simulation using a digital twin. This case study demonstrates how knowledge graphs and generative AI can be leveraged to build a digital twin to efficiently reconfigure a factory. Knowledge graphs represent factory equipment, processes, and related data in a graph structure, allowing you to clearly understand relationships and influences. Generative AI, on the other hand, is a technology that generates new designs and processes based on data, supporting the efficient reconstruction of factories. Combining these technologies enables factory reconfiguration simulation using digital twins, enabling more efficient and flexible factory operations.

Summary

Leveraging digital twins can make factory operations more efficient and automated. Combining technologies such as knowledge graphs and generative AI has enabled factory reconstruction simulations using digital twins, opening up new possibilities for the future of factories. With future technological advances, digital twins and AI will dramatically change the future of factories.

Conclusion

This content based on reports from members on site participating in DAIS sessions. During the DAIS period, articles related to the sessions will be posted on the special site below, so please take a look.

Translated by Johann

Thank you for your continued support!